TL;DR version: I got to borrow the littlebits synth kit, and created a parametric version of the mounting board. The source files are available on github: https://github.com/osbock/Baldwisdom/tree/master/LittleBitsMounts

The Newton Free Library applied for and got a cool LSTA ( Federal Library Services and Technology Act) Grant to do a bunch of STEM related programs, and I have the honor of doing a bunch of coding and robotics workshops there over the next few months.

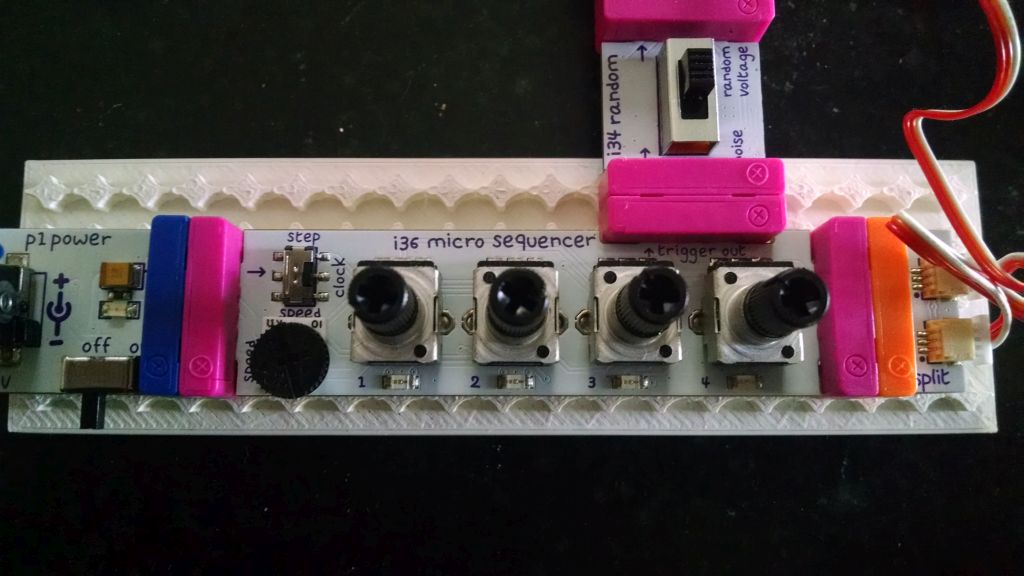

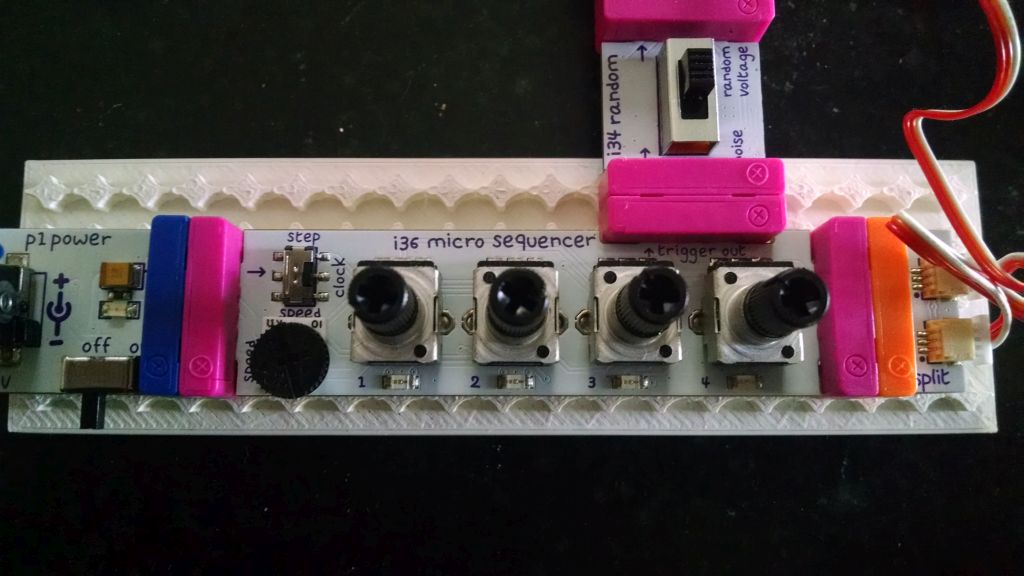

They got a bunch of cool new equipment to run these programs including Finch Robots, Arduinos (Sparkfun Inventors Kits), a KIBO robot, and … wait for it… a bunch of Littlebits sets. NFL Assitant Director Jill Grabowski was kind enough to lend me the coolest littlebits set: The Korg Synth kit.

If you aren’t familiar, they are modular electronics blocks that snap together with magnets. Unlike earlier “electronics construction sets” these are pretty foolproof, well thought out modules instead of just individual components. As Founder Ayah Bdeir says ,

AT LITTLEBITS, WE ARE ON A MISSION TO DEMOCRATIZE HARDWARE BY EMPOWERING EVERYONE TO CREATE INVENTIONS, LARGE AND SMALL, WITH OUR PLATFORM OF EASY-TO-USE ELECTRONIC BUILDING BLOCKS.

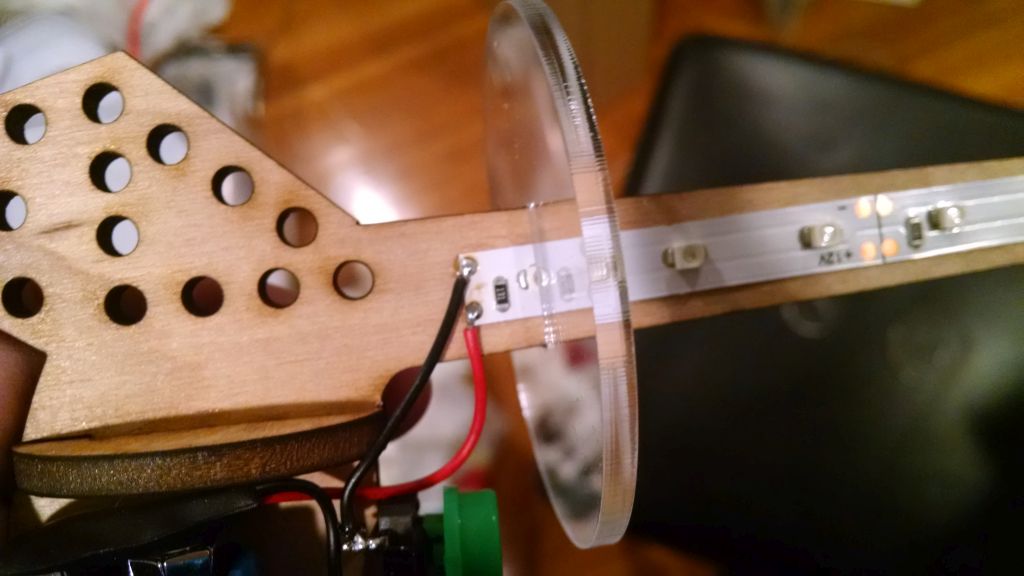

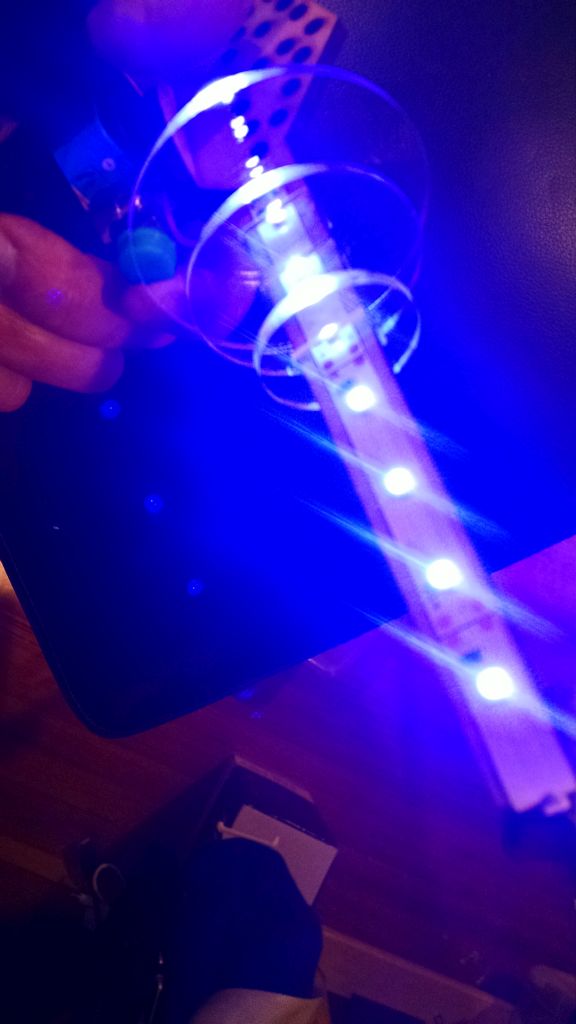

Unfortunately the thing that makes Littlebits easy is also it’s greatest weakness: The magnetic connection system.

Especially when making something you have to manipulate (like a musical instrument), they tend to come apart, you lose power, etc.

Now some of the other (more expensive) sets come with mounting plates (that you can also buy separately. I didn’t have one though, but I do have a laser cutter and a 3D printer. How hard could it be? Well, the devil is in the details.

First I looked to see if it was already done. Thingiverse (I know boo….) has a few designs, including some by littlebits themselves, mostly specific component mounts.

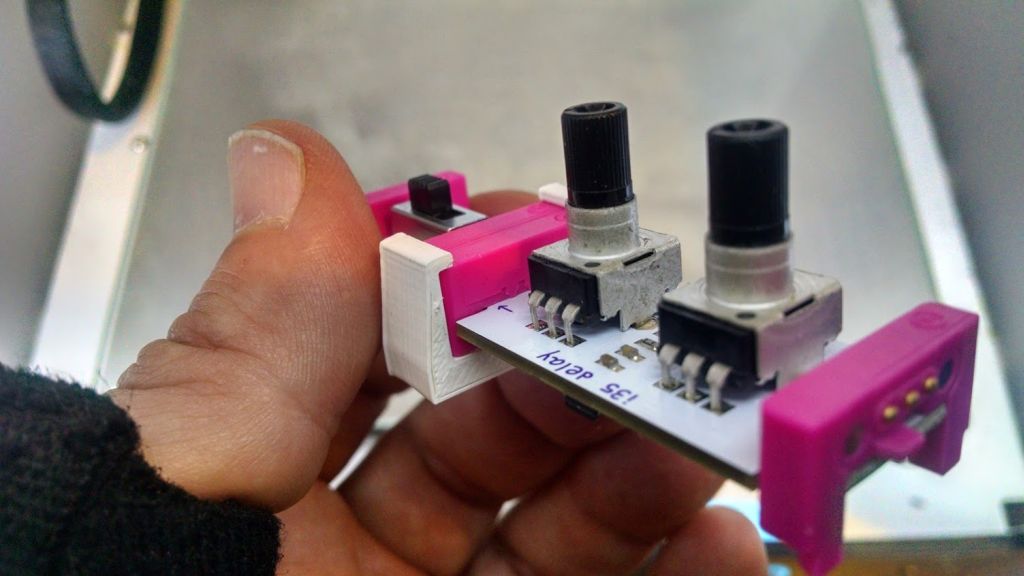

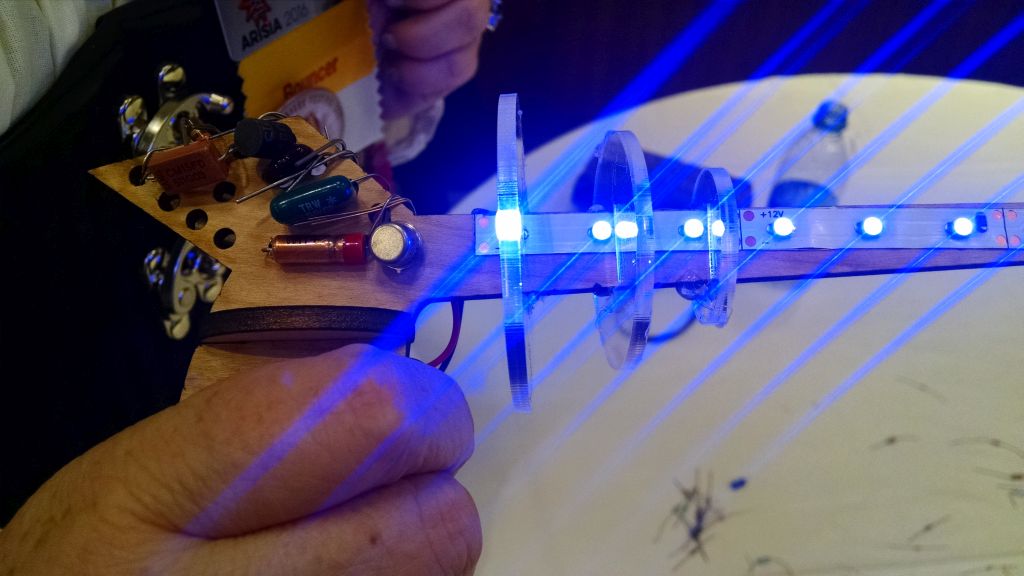

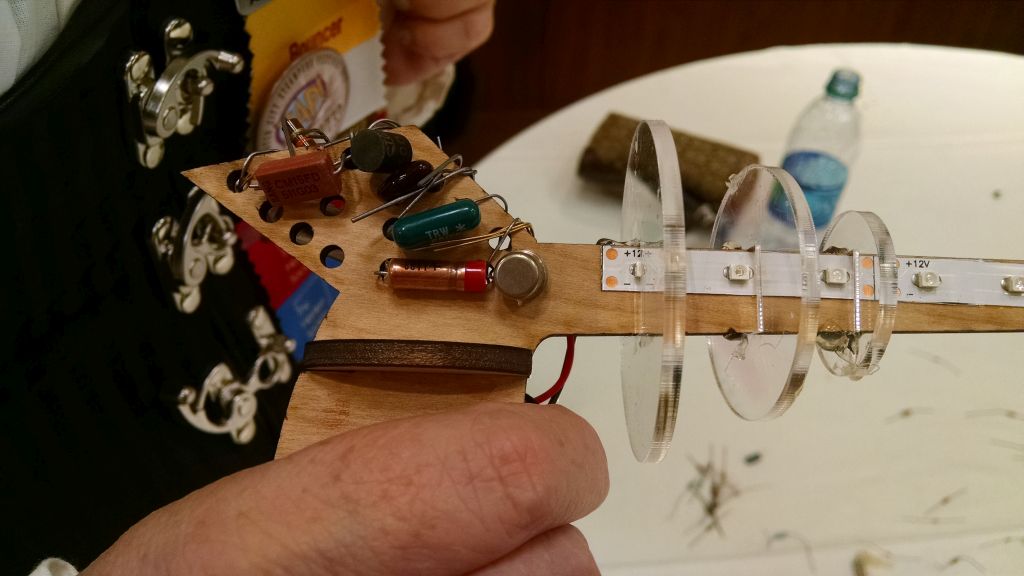

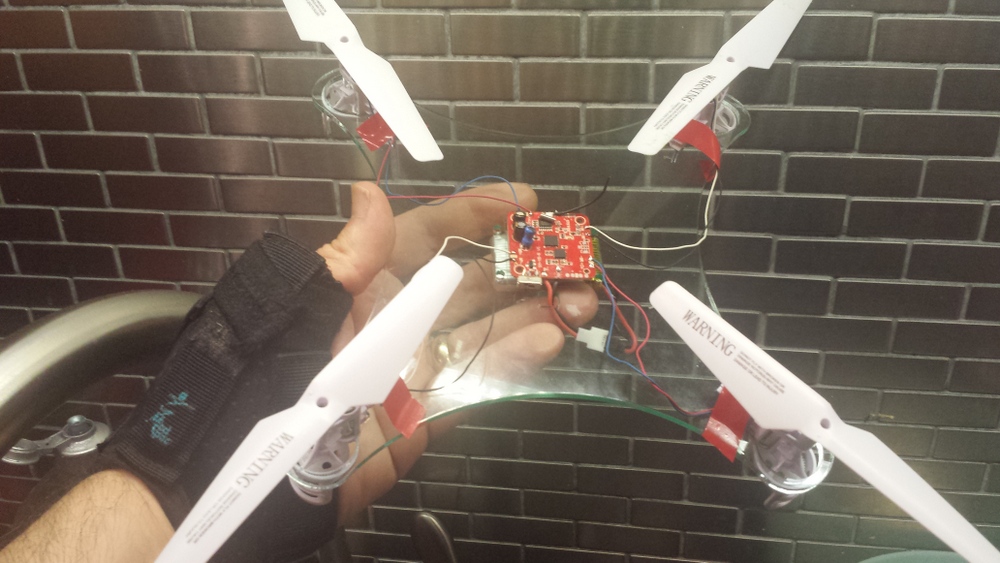

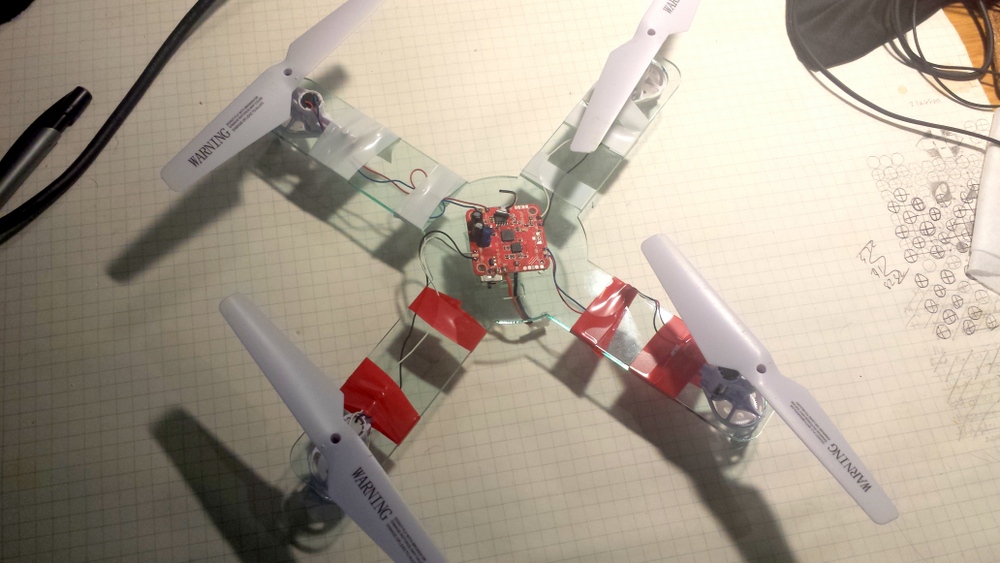

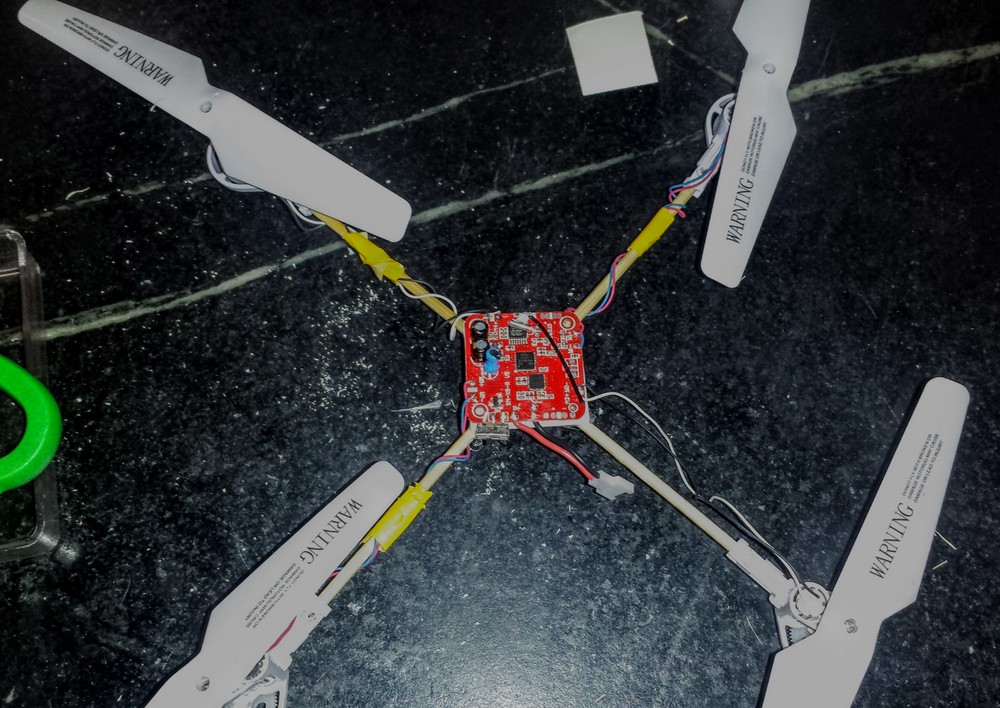

Rex Brodie posted this cool clip that fastens adjacent modules together.

It works pretty well (very solid) but it was difficult to put the two bits in without pulling and pushing and putting a bit of strain on the boards. (Especially scary when the ‘bits are on loan).

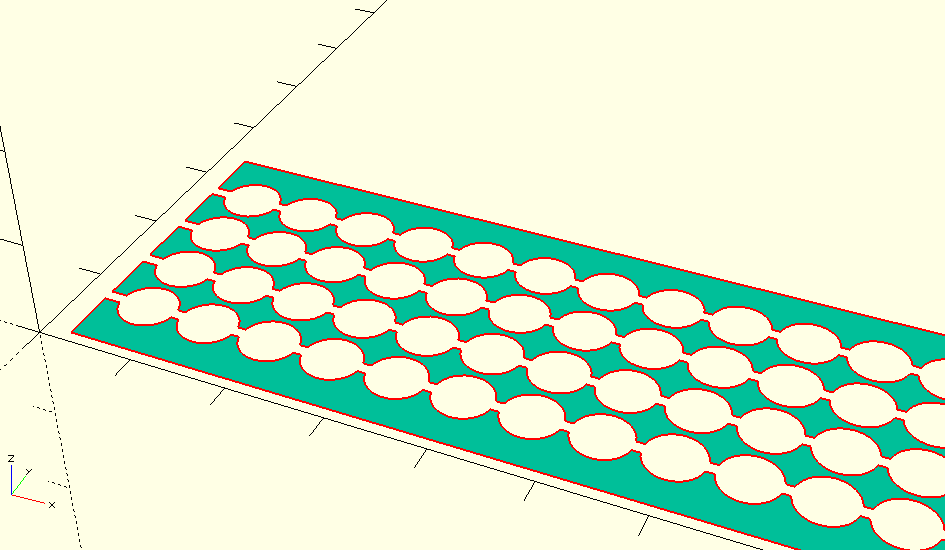

I tried just measuring and cutting holes with my laser, or a simple model with Open SCAD but I just couldn’t get the spacing quite right.

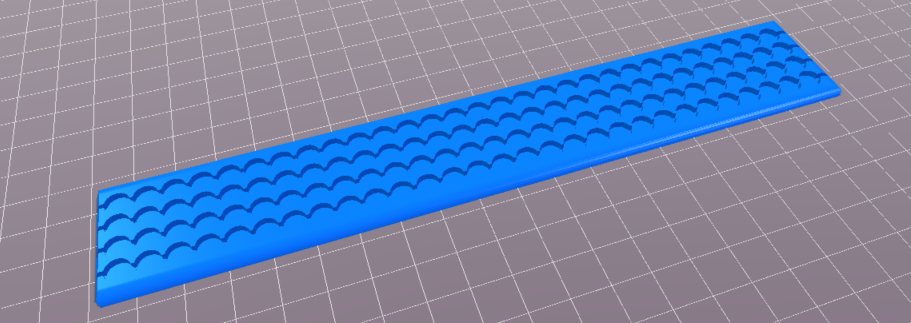

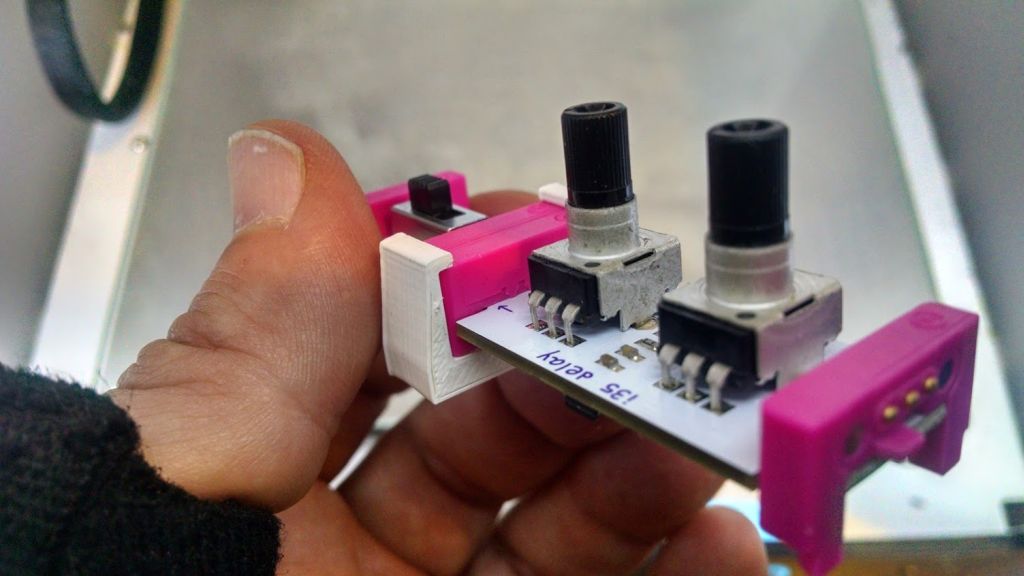

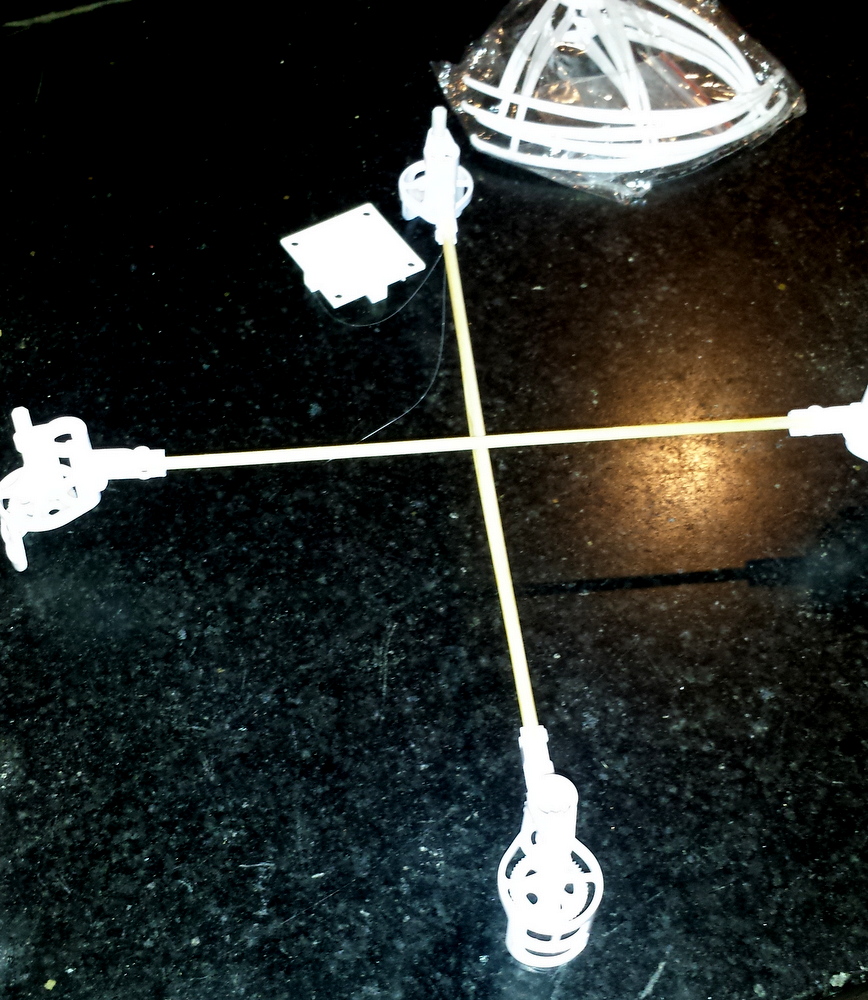

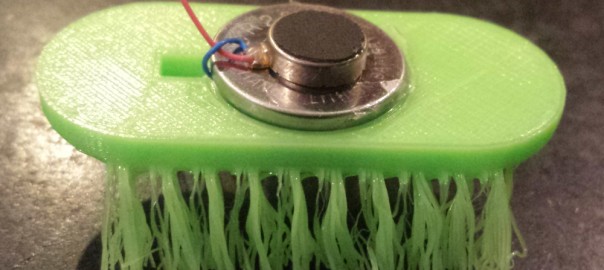

Thingiverse user Kris Kitchen had posted this design:

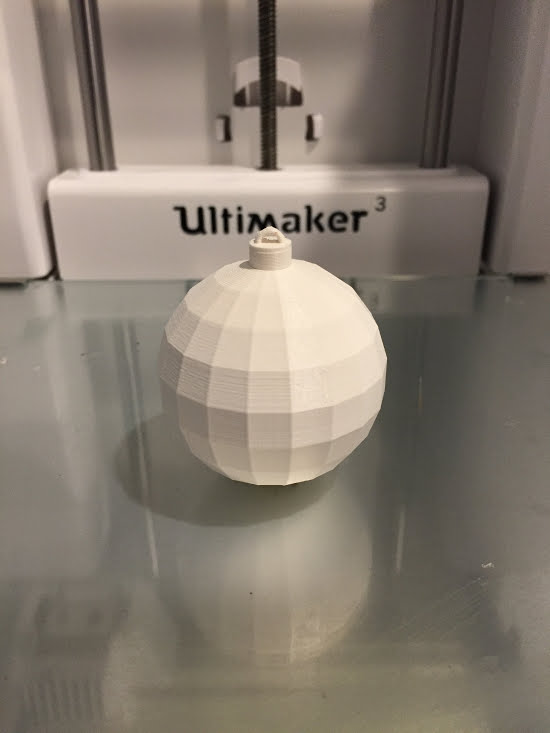

which I printed and actually worked quite well. Only problem was, it was an STL (Surface Tessellation Layer) file, and thus not easily modifiable. I wanted wider, arbitrary shapes, etc!

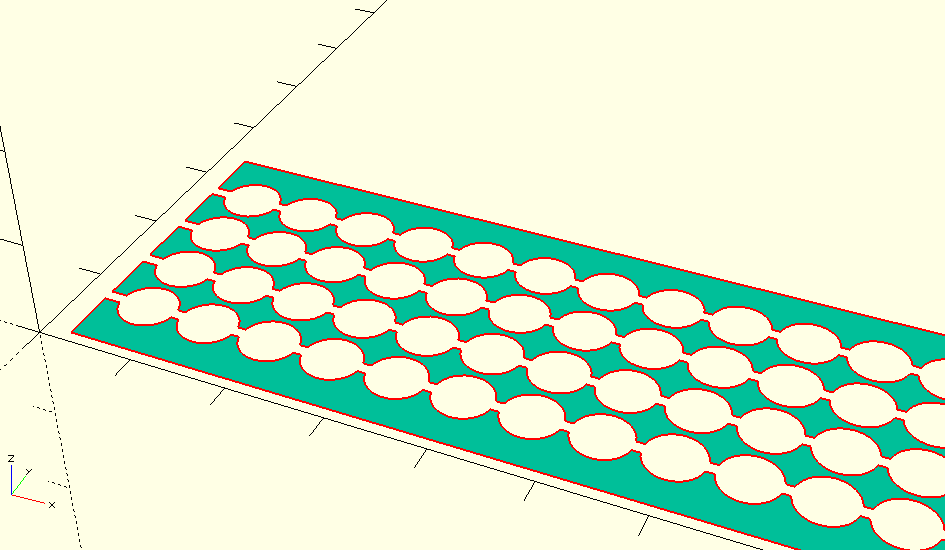

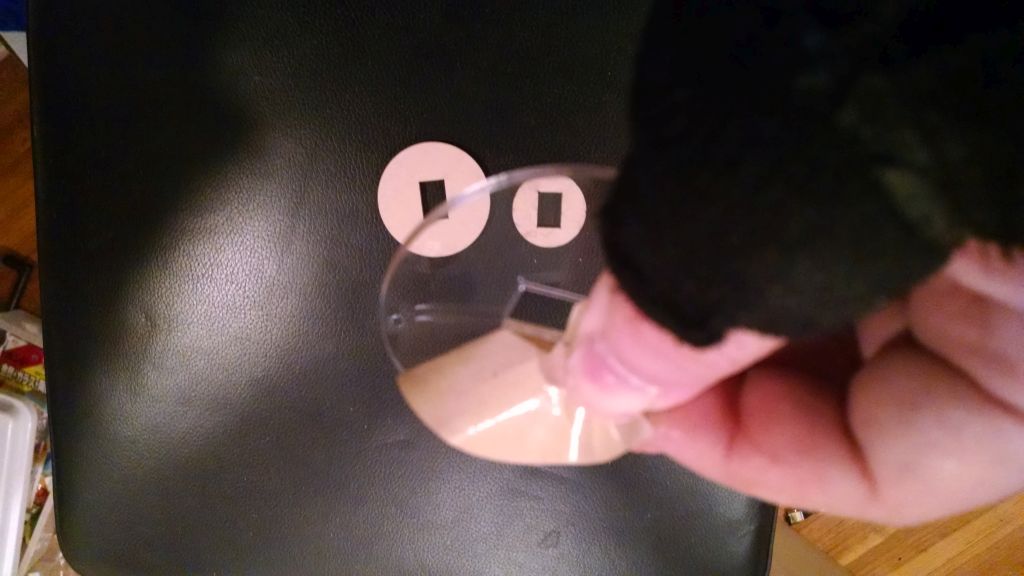

I could however pull Kris’s design into OpenSCAD, and do a trick to measure the “holes” and spacing.

This little bit of code:

[code]

projection(cut=false)difference(){

translate([0,0,-41])import(“LittlbitsGridthin.stl”);

translate([0,0,-10])cube([250,40,10]);

}

[/code]

cuts off the bottom so the holes will show and projects the outline in 2D.

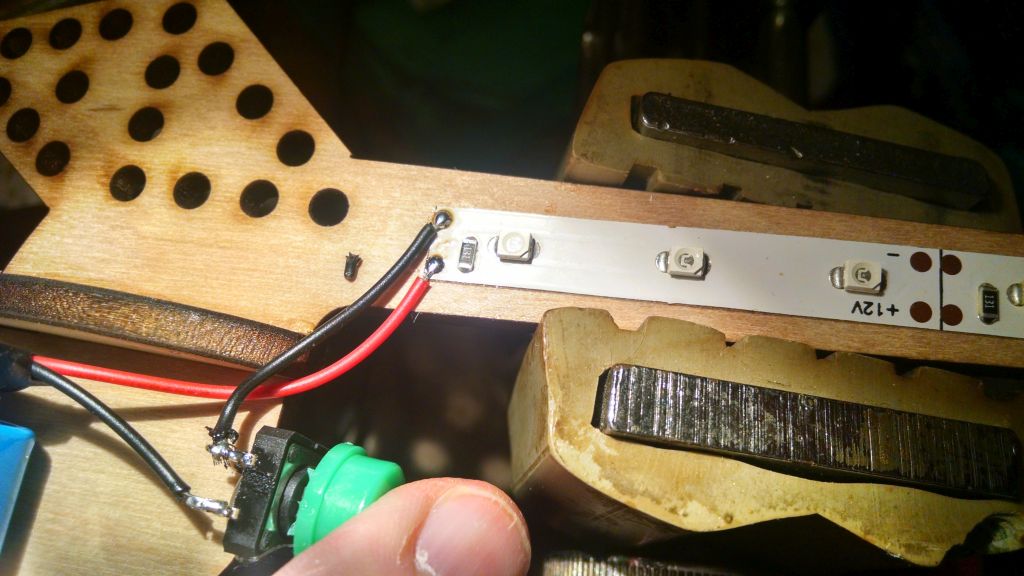

I then exported this as a DXF file, and used inkscape to make measurements.

If I haven’t lost you by now, the part you are waiting for, the measurements (which I couldn’t find anywhere after much googling!)

- Holes: 6 mm diameter

- Spacing (edge to edge or center to center): 6.63mm

- spacing is also 10.5% of hole

- 1.294mm knockout line

The percentage bit is important (I calculated it, 6.63/6) if you are designing in inkscape because that is how you do a grid of evenly spaced objects.

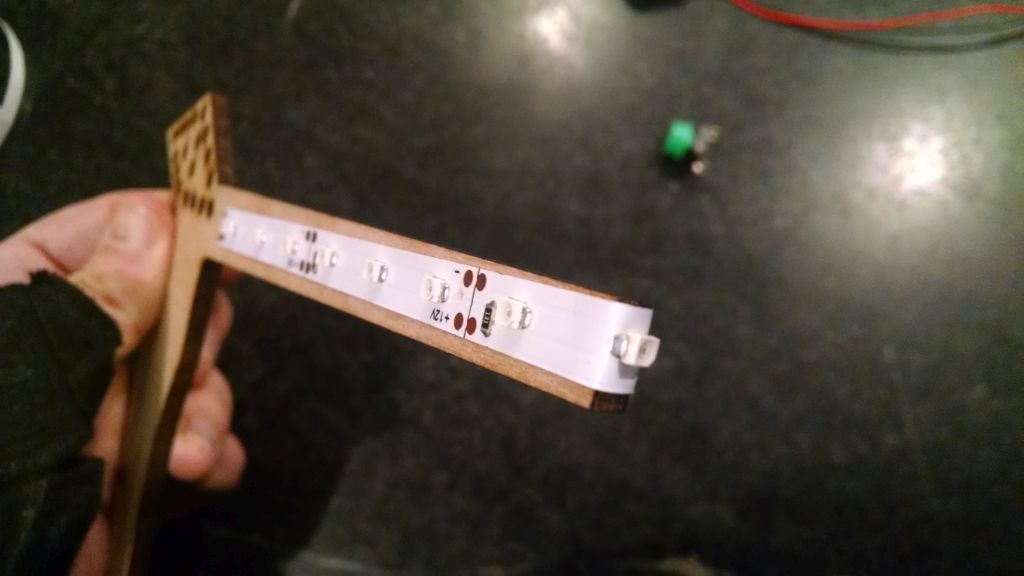

I made a couple of attempts at a laser cut version, but it was very brittle, and I didn’t take into account the laser’s kerf (width of cut)

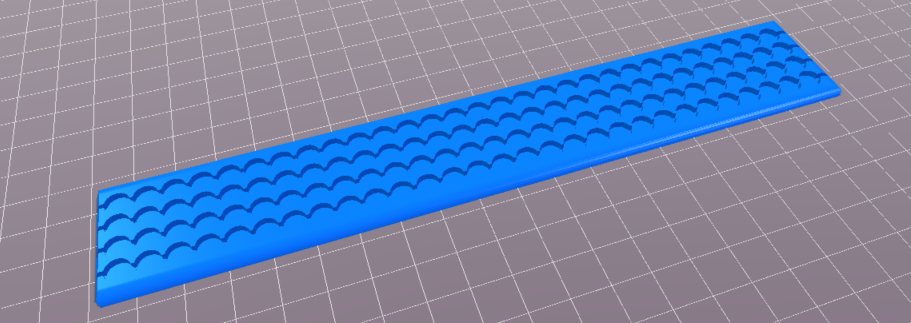

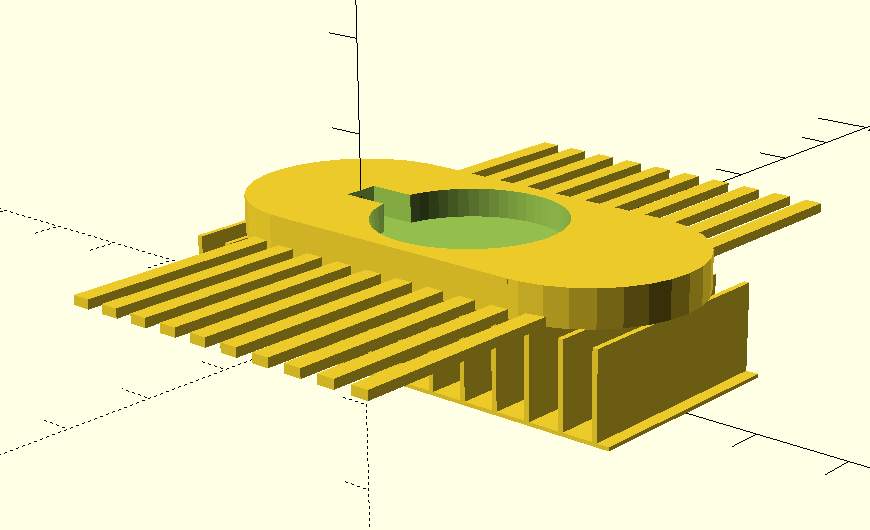

The 3D printed version came out pretty well, but the holes were a bit too small, so I enlarged them by .2mm (.1mm on the radius). and it worked perfectly!

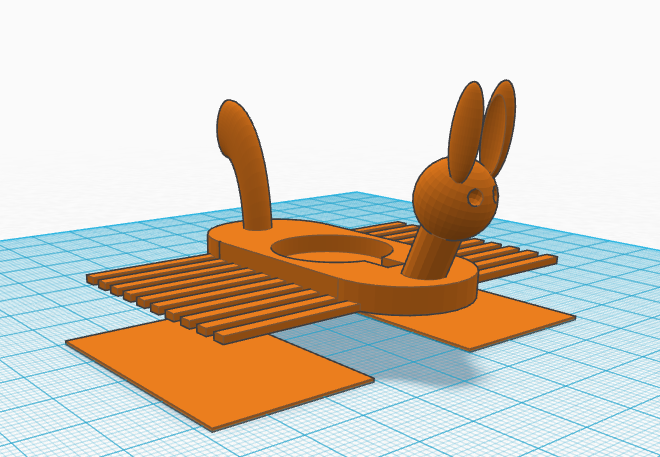

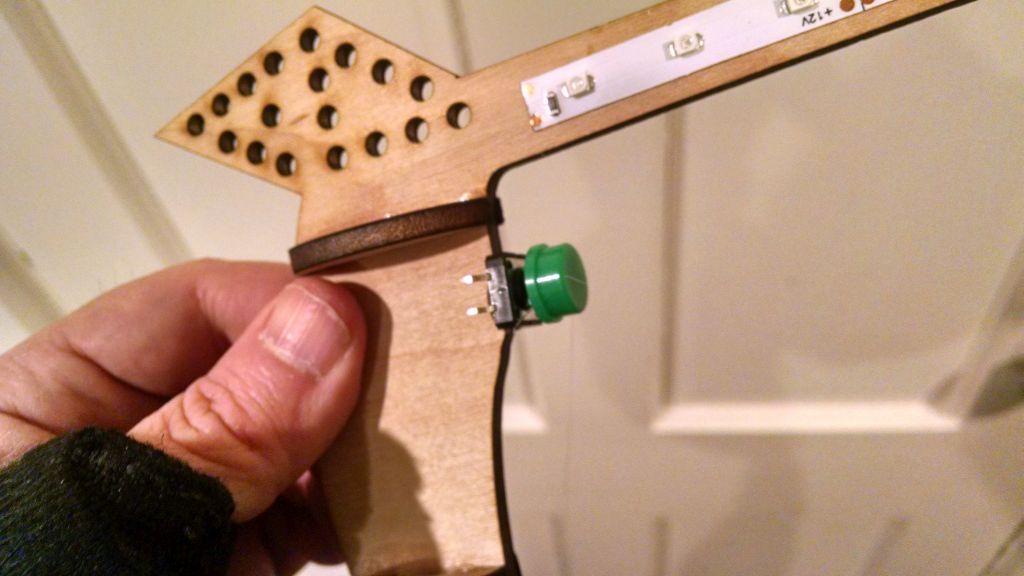

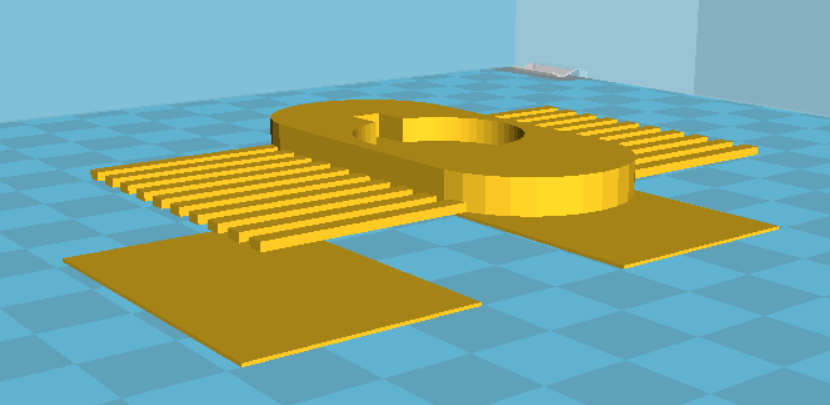

Now we can make mounting boards in any shape!

The source files are available on github: https://github.com/osbock/Baldwisdom/tree/master/LittleBitsMounts

This works out quite nicely, and gives a speedier print.

This works out quite nicely, and gives a speedier print.