When I took my Mini Cooper in for it’s annual state safety and emissions inspection it failed because one of the tail lights was out, and the license plate lights were, well really out. One of the lenses had long ago fell out, and the other bulb was dead.

When I looked on line, the cost for a couple of lenses and the bulbs was greater than a complete unit with LEDs (never replace again!) so I ordered a pair from ebay. They came, but the contacts wouldn’t make connection with the bulb holders.

When I looked on line, the cost for a couple of lenses and the bulbs was greater than a complete unit with LEDs (never replace again!) so I ordered a pair from ebay. They came, but the contacts wouldn’t make connection with the bulb holders.

I communicated with the Ebay seller, and they were great, offering me a refund or to find the right bulbs for me, but I was impatient.

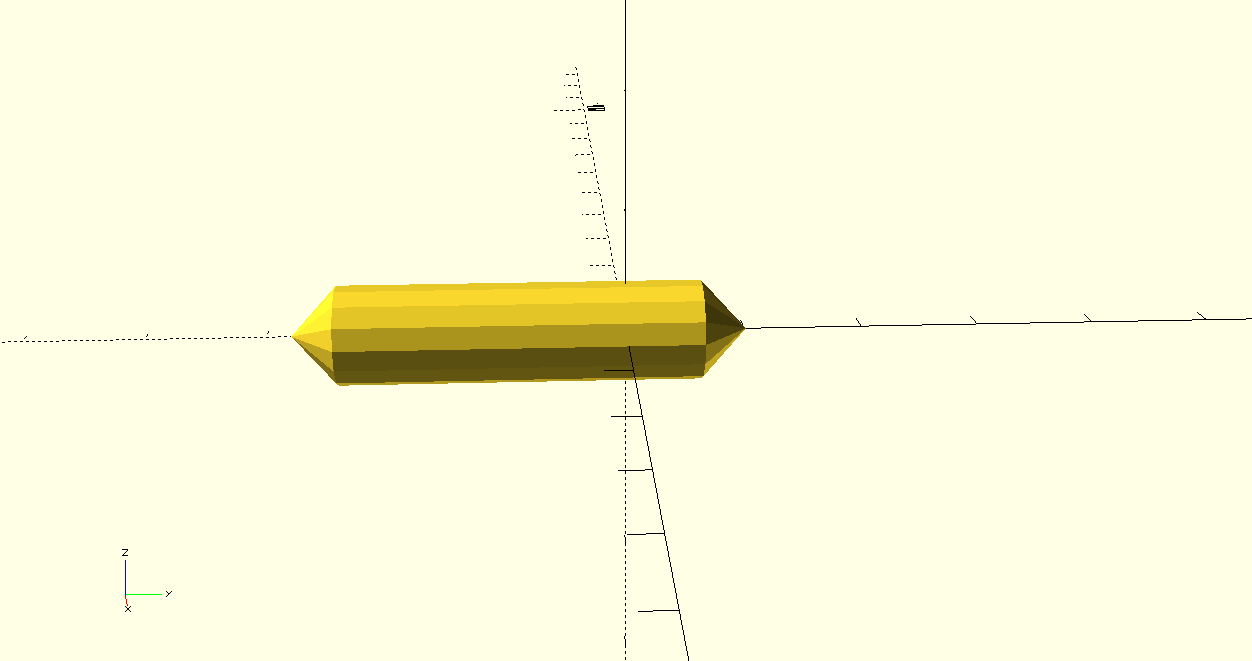

I decided to make a bulb proxy and solder wires between it and the new LED fixtures. It only took 10 minutes to whip something up in OpenSCAD:

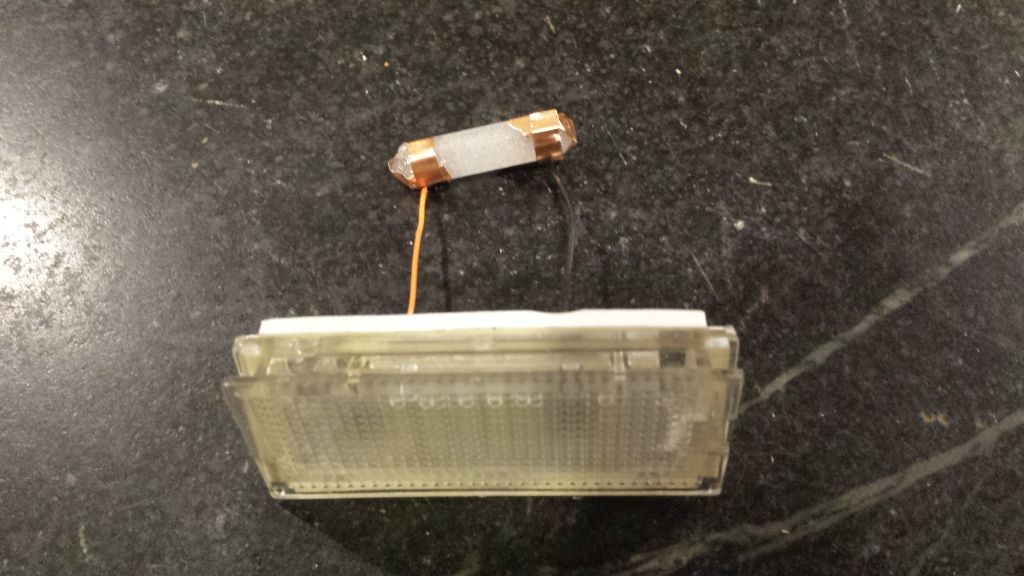

It didn’t have to be pretty it just had to fit and hold the contacts in place. For contacts I wrapped the ends in copper tape, and soldered wires between those and the light fixtures.

Note, that it’s easier to solder to any delicate surface if you use liquid flux.

The result was fantastic (pay no attention to the filth on my car….)

Hopefully it will pass inspection tomorrow. Of course if I didn’t have all this stuff at home, it totally wouldn’t have made sense to do this, but I do, and it was actually a fairly fun and easy project.